Why is material prep important with thread rolling?

Thread rolling is a cold forming process and the material goes through a state change. With Axial rolling tools this change normally occurs in the first 2 pitches.

Material is prepped at the mean of the Pitch based on the class of thread.

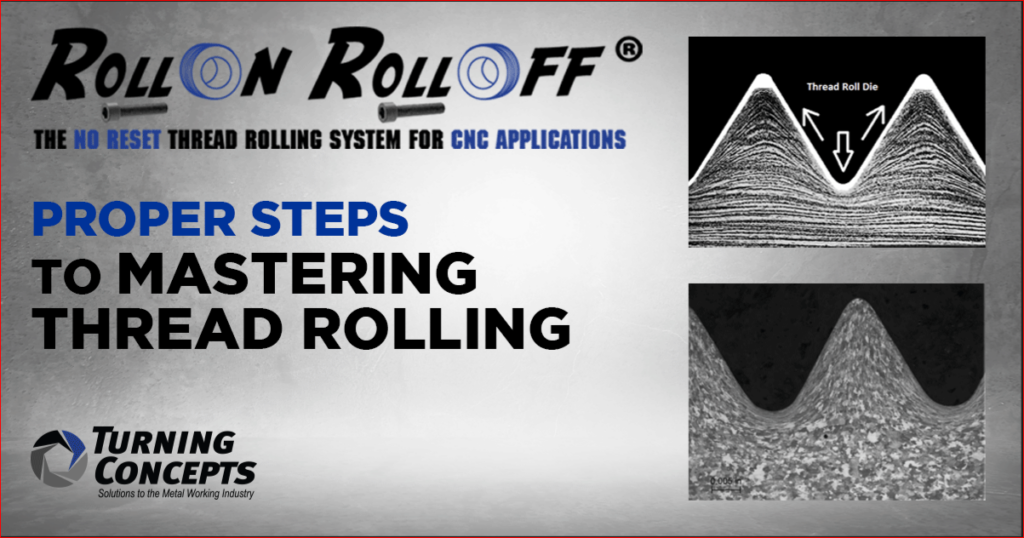

The state change occurs by compressing the material down to the Minor dia then it flows up the roll form and creates the Major.

The chamfer must start a least .010” below the Min. Minor

Improper prep results in too much material and risks breaking the rolls