Tool setup

- Mill a .250” to 375” flat on the shank within .500” of the head if not already there.

- The tool is assembled and setup. The rolls are set with a gauge pin to the max Minor less .002”. see below

Machine setup

- Mount tool and sweep faceplate OD with an indicator – TIR total .005”

Process setup

- Use sacrifice material- program a .600” length to test roll a .500” long part, Insure the material will not hit faceplate.

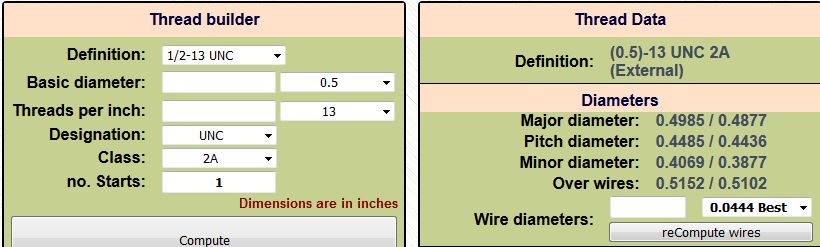

- Pre-turn for rolling = Mean of the Pitch or __.445”__

- 30’ chamfer starting at .015” under min. Minor. ___.372”____

- Feed rate is Pitch less .0005” or ___.0764”__ Roll on and off at the same federate.

- Sync tap (G84, G77) works best. G34 with M03,04 spindle reverse- no dwell.

- SFM- 125 SFM for low carbon steels, 100 SFM for SS and hi-nickel. Increase after good part. Call for confirmation.

Call before you hit cycle start. 704-849-9209

Adjusting after first test roll-

Step 1- Minor Dia. and Pitch Adjustment-

- Loosen 3 nuts and adjust tool +/-. One witness line is .004”on Minor. Center Pitch.

Step 2- Major Adjustment-

- Adjust pre-roll dia to the mean of the Major. .001” change in pre-roll dia. = Major dia. change of .003”

Step 3- Adjust chamfer

- Adjust for desired result. Keep chamfer min of .010 under min Minor. Material will “rollup about 15’. Alternative- cut after rolling.