Nearly everyone loves to watch a video to learn something new. We made it possible for you to learn how to thread roll by watching our YouTube page and contacting us for more information to be sure you understood the process. Click the link and start your thread rolling journey.

WHY THREAD ROLL WITH LMT FETTE PRODUCTS

- Thread rolling productivity is the cycle time of a single pass. If you make 5 single point thread passes rolling is 20% of your current process time.

- Cost per inch of threads produced by CNC machines is normally $0.20.

- Fette’s selection of rolling attachments is the broadest available.

- Roll on Roll Off® is ideally suited for CNC

- Barfeed applications and high cost material.

- All manufactures processes where the thread is the last feature created as error proofing is a CNC control function.

- Requirement of a stronger thread as strain hardening occurs during the material state change.

THREAD ROLLING PRODUCTS

We are a leading distributor in thread rolling products offering axial, tangential and radial thread rolling options. Whether your application is a standard UNC or UNF thread with a normal length or a special UNJ thread with a long or short thread, we can evaluate the application and find the best thread rolling solution. Keep in mind, some UNJ rolls are stocking standards and may be available on the shelf.

If the thread rolling application is on a CNC machine, inquire about the Roll On Roll Off ® thread rolling system. It’s a no reset application. Find out how to capture cost savings utilizing this process.

Find thread rolls here. Contact us to check stock.

THREAD ROLLS, FETTE ROLLING HEADS, SHANKS AND MORE

Although you typically will not find a thread rolling head under the tree or in a stocking, you may find it on a machine. The excitement is overwhelming knowing all the time you’ll save rolling threads instead of single pointing threads. A thread rolling head is a wise investment for your machine shop. All manufacturing facilities should have this tool to cold form threads faster than reindeer can fly.

Call us if you need thread rolls or thread rolling attachments. We’re here to guide you through the process.

Roll On Roll Off®️ TECHNOLOGY with the FLANGE-MOUNTED SYSTEM for LARGE THREADS

Get to know the Roll On Roll Off®️ technology with the flange-mounted system for large thread CNC turret lathes. Some of the design features include:

✅ A one piece flange mount turret block

✅ Increases strength and reduces weight

✅ Flange rolling tools don’t have the thread diameter limit caused by a shank

✅ Designed to fit most models of CNC turret lathes

YES YOU CAN THREAD SMALL THREADS

Think your thread is too small to thread roll? Let’s see. We offer tooling to roll threads as small as 0X80 on your Swiss. Think the head won’t fit on your machine? We have a solution for up to a 32mm machine from 1/4″ all the way to a 5/8″ thread. Thread Rolling is an economical solution for your Swiss machine and our patented Roll On Roll Off® system will eliminate the need to reset your head.

Our Roll On Roll Off® system is continually evolving to meet new challenges with more and more complex parts.

Over the past year, we have refined our ability to compensate for long parts and give our tools up to 0.500” of separation to allow for Roll On Roll Off® to be utilized on parts that were previously limited in length. This system is adaptable and can be removed easily without having to change any setups.

With a simple removal of a few screws, your tool will be able to pop open to assist in setup. This cuts down the need to remove the tool from your machine saving you valuable time. The flange mount system is more rigid while also not limiting length for threads larger inside of the range of the Fette tool.https://fette-tools.com/ https://www.geneseemfg.com/

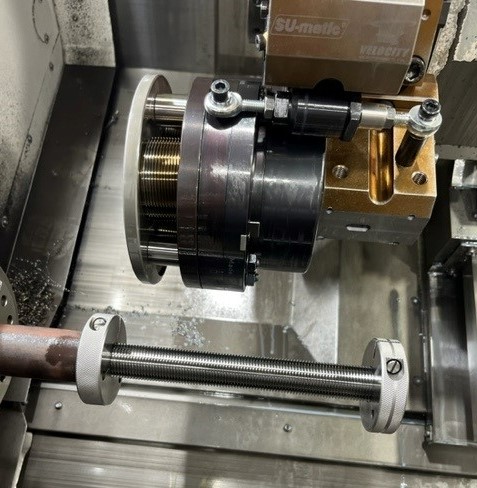

IMPROVE YOUR CYCLE TIME – PRODUCE MORE THREADS

Our customer, a tool manufacturer of their own product, initially inquired 4 months before the tools were delivered to them. They make their product out of 4340 steel that comes in around 35 Rockwell C. They have seen a growth in business of 30% for the last 6 years and are running bar feed lathes, with a current capacity of 7 machines. Initially, the product line that was submitted contained 22 parts, with 9 of them sharing the same 1”x12 thread. The longest of these threads was 8”, thus creating the necessity in a Roll On Roll Off® tool with extra compensation. The design, pictured, added external springs to the Roll On Roll Off® device to allow the head to make the threads at that length and avoid “popping open” as the traditional method requires and necessitates a closing solution. Turning Concepts’ idea was to never let the head open to begin with, so there would be no need to facilitate a closing solution.

With the review of the customer’s parts, the F4 and F45 thread rolling heads were selected as a test tool on a single machine to qualify the feasibility and the reduction in cycle time. The threading cycle for single point cutting the customer started with was 3 ½ minutes. The customer’s floor space was limited as they are running bar feed machines, so the possibility of drastic reduction in cycle time through the addition of thread rolling is appealing to the customer. The customer selected 1 machine to add a Roll On Roll Off® tool for both their 1”x12 thread and the 3/4X16 thread accompanied by a Genesee hollow mill to further reduce their cycle time in preparing the workpiece to the correct pre-roll diameter for rolling. The Genesee hollow mill is an encapsulation tool that feeds at 200 SFM and makes a perfect cut in a single pass. With this combination of tools, a finished thread is completed in 2 passes and will not require deburring after the part is completed.

The tools were delivered within 4 months of the initial inquiry from the customer and per their request, on-site support was provided. Threads were made in the first 4 hours of on-site support and the process was improved until a current thread cycle time of less than 60 seconds for both tools were achieved for 8” of thread. This improvement in cycle time will allow production gains in a single machine that can be duplicated on their 7 additional machines through the end of the year. The process is ongoing and further improvements may be seen throughout this development process. The initial on-site support has been supplemented through email and phone support from both Turning Concepts and Genesee for both the hollow mills and the thread rolling tools. With the quick reaction time from our experts, the customer has been running parts since the installation without a problem from our quick delivery Roll On Roll Off® tool adapted to meet the customer’s demand.

Gen Dex

Roll On Roll Off®️ Thread Rolling system can make NPT threads

Since the RORO system doesn’t allow the rolling attachment to pop open, the system by design is error-proofed. Failure to pop open eliminates the highest risk of damaging the rolling attachment.

It can produce a wide range of thread types, including NPT. These threads are used in a wide range of industries – plumbing and pipe fitting, power plants, gas and oil, chemical and manufacturing.

AXIAL THREAD ROLLS IN STOCK

We have rolls in stock. What size do you need? If you need them coated, we have coated rolls in stock too. If we don’t have the size you need coated, we can get them coated.

Call or email us to find out availability.