FLANGE-MOUNTED SYSTEM FOR LARGE THREAD CNC TURRET LATHES

Use the Genesee hollow mills on machining centers and lathes.

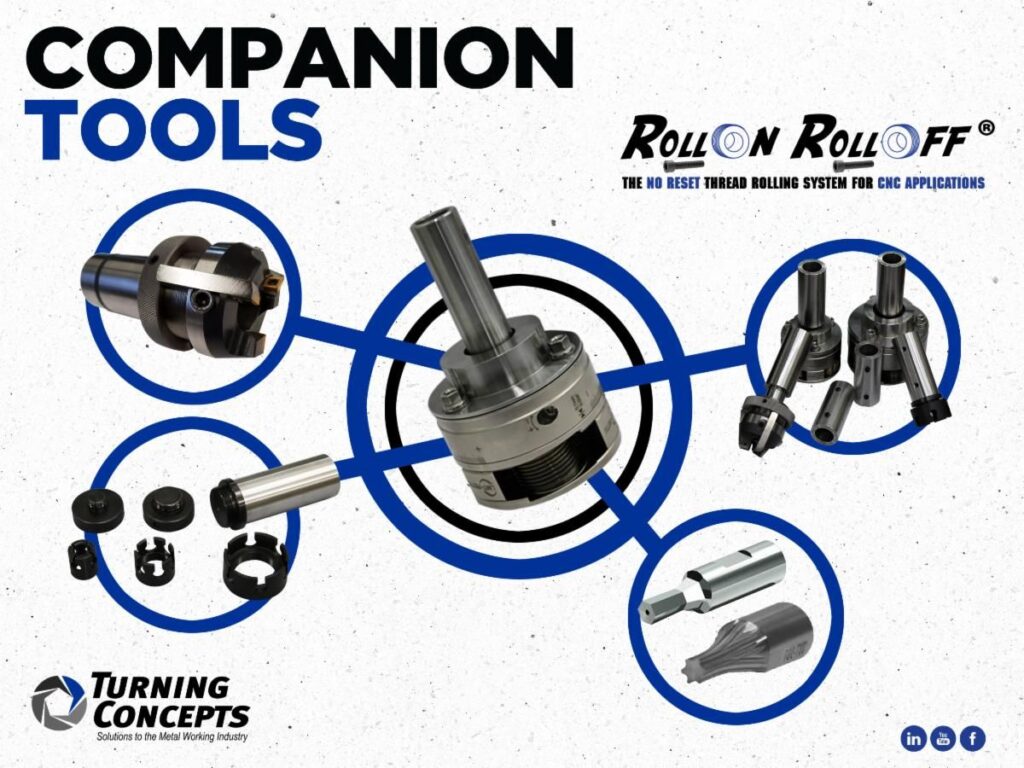

Products shown include Hollow Mills, Sleeves, Rotary Broaches and Thread Rolling Attachment

The last step in proper rolling is executing and adjusting after first test roll.

Step 1 – Minor Dia. and Pitch Adjustment

Loosen 3 nuts and adjust tool +/-. One witness line is .004”on Minor. Center Pitch.

Step 2- Major Adjustment-

Adjust pre-roll dia to the mean of the Major. .001” change in pre-roll dia. = Major dia. change of .003”

Step 3- Adjust chamfer

Adjust for desired result. Keep chamfer min of .010 under Min Minor. Material will “rollup about 15’. Alternative – cut after rolling.

The fourth step in proper rolling is setup of the Process.

Using sacrifice material- program a .600” length to test roll a .500” long part, Insure the material will not hit faceplate.

Pre-turn for rolling = Mean of the Pitch or .465”

30’ chamfer starting at .010” +0.0 -.020’ under the Min. Minor

Feed rate is Pitch less .001” or a proprietary calculated material dependent amount. Roll on and off at the same federate.

Sync tap (G84) works best. Std Tapping cycles and G34 with M03,04 spindle reverse- no dwell.

SFM- 125 SFM for low carbon steels, 100 SFM for SS and hi-nickel material.

The third step with proper rolling is the Machine Setup. Mount tool and sweep faceplate OD with an indicator – Rolling requires TIR of .005”

The second step with proper rolling is the Tool Setup.

Mill a .250” to 375” flat on the shank within .500” of the head if not already there.

The RORO tool is assembled and setup. The rolls are set with a gauge pin to the max Minor less a proprietary calculated amount based on the material.

Why is material prep important with thread rolling?

Thread rolling is a cold forming process and the material goes through a state change. With Axial rolling tools this change normally occurs in the first 2 pitches.

Material is prepped at the mean of the Pitch based on the class of thread.

The state change occurs by compressing the material down to the Minor dia then it flows up the roll form and creates the Major.

The chamfer must start a least .010” below the Min. Minor

Improper prep results in too much material and risks breaking the rolls

Step 1: Material Prep

Step 2: Tool Setup

Step 3: Machine Setup

Step 4: Setup Process

AND

Step 5: Adjust Machine

The rolls are likely worn or chipped. Flip the rolls over and use the other side of the rolls.